Condition Monitoring of Extraction Systems to Ensure System Availability and Reduction of Maintenance Cost

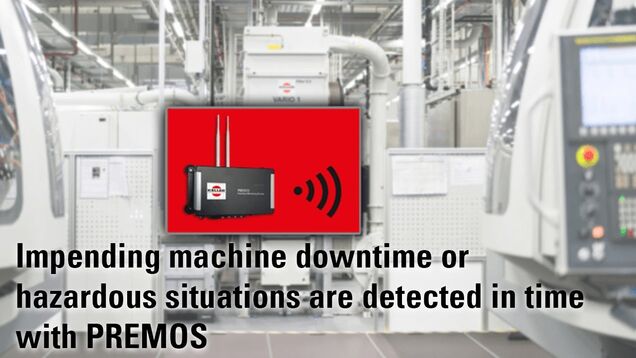

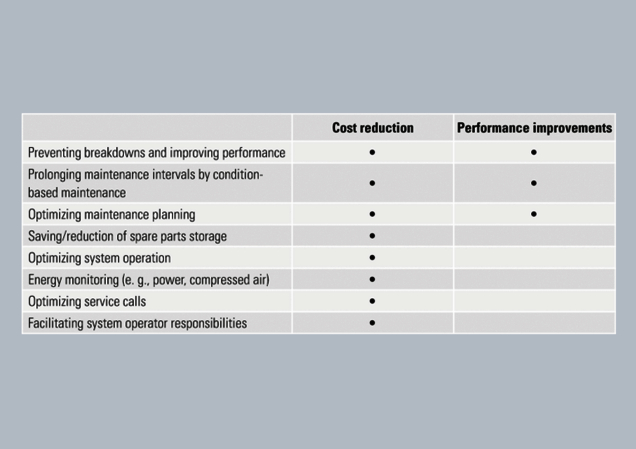

In case of a machine failure production cannot continue often for several processing machines/workstations. This can lead to considerable costs up to non-performance of the delivery obligation. Because of services of Keller the system availability shall remain. Therefore, condition monitoring is a new service allowing a permanent remote monitoring of the system's status. The aim is to warn the customer in time, before issues come up on the customer's systems. Thus, unscheduled system downtime is avoided, and maintenance costs are reduced.

Simple and Safe Retrofitting

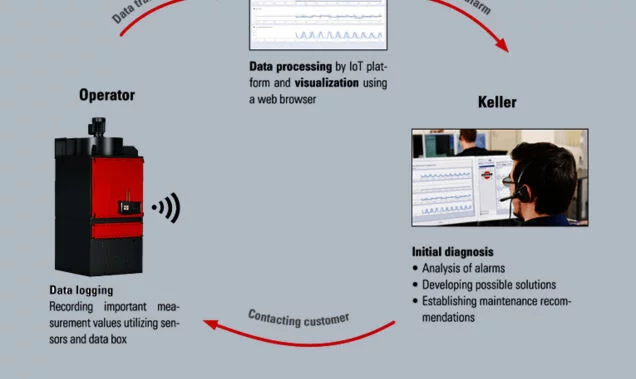

The system's hardware includes a data box and a sensor package which can be easily retrofitted. No IT infrastructure is necessary - data transfer happens via mobile communications and is separated from the system's control unit. Exceeded limit values are displayed on a web-based data platform. After an initial diagnosis of the system data the operator will be informed to agree upon suitable measures or maintenance recommendations.

Downtime risk close to zero with the use of Predictive Monitoring

Abstract Customer MagazineSchweizer Group: "No more downtimes – Predictive Monitoring pays off"

Abstract Customer Magazine