Wet Separation Provides the Better Solution

Wet scrubbers are used in the absorption and scrubbing of vapors or particulate waste that either can‘t normally be separated or are difficult to separate in dust operating systems.

The degree of separation is often higher with dust collectors, but for combustible, moist, sticky or adhesive emissions, such as those generated during polishing or blasting, wet separation is the safer and more reliable option.

Venturi Wet Scrubber VDN: for Combustible, Explosive, Moist and Adhesive Dust

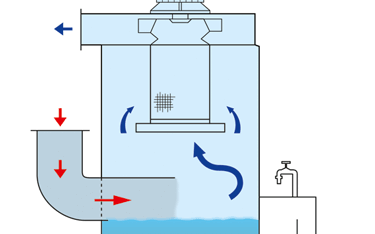

The venturi wet scrubber models inject water into the airflow as the basic concept of the venturi principle and are utilized in most industry sectors and metalworking applications such as polishing and grinding.

Venturi wet separator extraction systems are also known as wet scrubbers or gas scrubbers.

During the extraction process an effluent gas stream is saturated with liquid in order to absorb any contaminants such as particulate, waste liquids or gases. Usually, fresh water is used for the scrubbing process.

5 Models - 5 Disposal Systems

There are five models with different types of disposals. Air flows from 2,500 m3/h up to 56,000 m3/h can be separated with the various models.

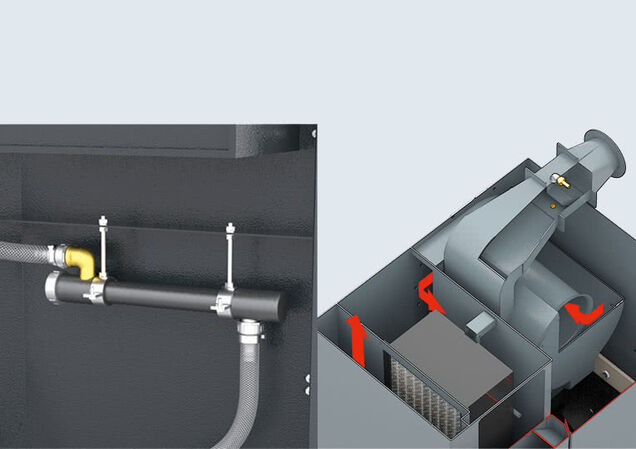

Compact Wet Separator HydronPlus: Collection Directly at the Workstation with Recirculating Air Operation

HydronPlus compact wet separator is geared toward manufacturing processes that create combustible, explosive or adhesive dust. It combines the explosion protection advantages of a wet separator with the high separation efficiencies of a dry operating process and thereby enables the recirculation of clean air.

A secondary filter stage in the wet separator ensures that the cleaned air readings are considerably below set particulate limit values. We can successfully recirculate the air back into the production plant. HydronPlus is not subject to the specifications of the Ordinance for Evaporation Coolers (42nd BImschV).

This new product advancement was awarded the Baden-Wuerttemberg Environmental Technology Award 2017 in the category of "Reduction of Emissions, Processing and Separation".