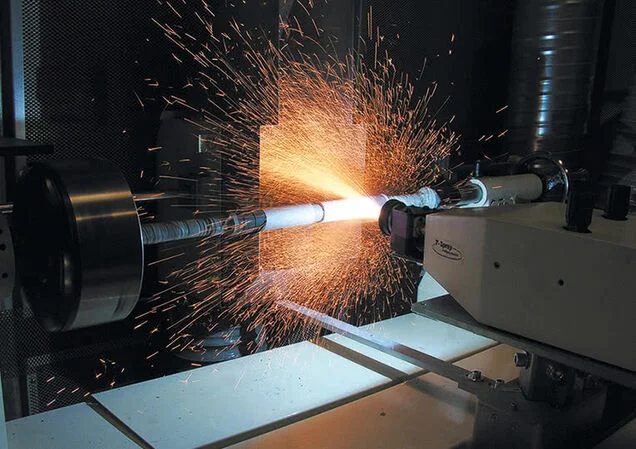

Extraction and Separation for Thermal Spraying Processes

In various spraying processes, not all the coating material ends up on the product. Part of the coating material escapes into the environment in the form of overspray/spray mist. Therefore, only efficient, precise collection and extraction will ensure a high quality end product.

Thermal spraying processes can generate a variety of hazardous material such as superfine, explosive or combustible matter, as well as harmful particulate. This requires strict adherence to legal and environmental regulations.

As a member of the GTS association, Keller possesses the latest state-of-the art technology concerning thermal spraying.

Individual Solutions for All Requirements

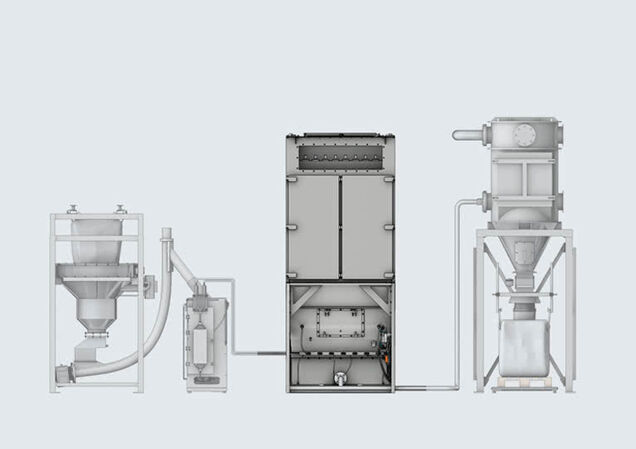

Thermal spraying is a process with various fields of application in all sectors of industry and crafts. Therefore, dust extraction systems must always be designed for the specific spraying method, the various materials and local circumstances.

For effective design and quote preparation, Keller prepared a questionnaire that includes the following:

- What type of material will be extracted?

- What is the required separation efficiency?

- What will be the method of disposal?

- What is the fire and explosion protection?

- What is the air flow?

The appropriate extraction solution for any coating process

Download BrochureReferences Thermal Spraying

These customers rely on our extraction systems during thermal spraying.

MTU Aero Engines AG, Munich - Germany (Engine technology)

Federal Mogul GmbH, Friedberg - Germany (Cylinder liners)

Sket GmbH, Magdeburg - Germany (Wind turbines)

TDK Electronics, Munich - Germany (Capacitors)

Ambau GmbH, Gräfenhainichen - Germany (Wind turbines)

... and many more!

Links

Used Products

Dust Collector VARIO eco >>

Dust Collector PT-Filter >>

Filter Element KLR-Filter >>

Explosion Protection

Information About "Explosion Protection According to ATEX" >>

Set and Guidelines

TA-Luft: Air pollution control - emission standards >>

42. BImSchV: Avoiding legionella risk in wet scrubbers >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 560: Luftrückführung bei krebserzeugenden Stäuben >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>