Clean Air During Casting Fettling Protects Personnel

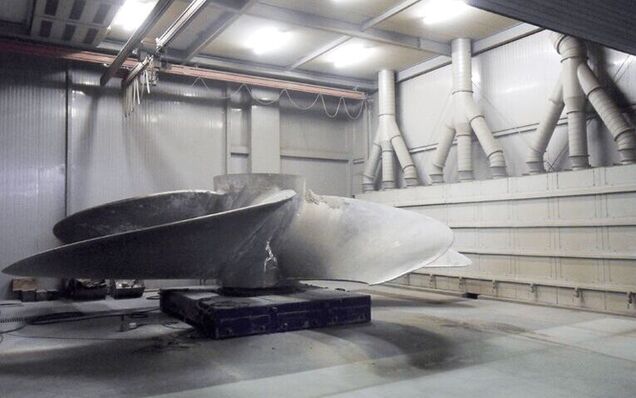

After blasting, the cast parts are released from the riser and feeder. The very fine metal oxides emitted by angle grinding, sawing or cutting must be thoroughly extracted. For larger castings flame cutters are used. This requires a large air supply, and the filter units are designed conservatively for extracting very fine dusts. Potential explosion protection measures must be employed if dust collectors are utilized for non-ferrous metals.

Flexible Extraction Solutions for All Materials

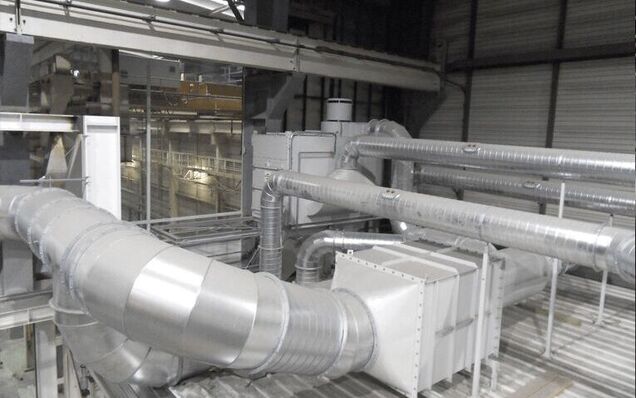

Dust extraction of ferrous metals is achieved with the benefit of a VARIO dust collector with KLR-filters. This solution provides a high separation efficiency and is very energy-efficient because of the opportunity for clean air recirculation.

For non-ferrous metals, wet separators are used with lower air flows, which result in lower initial investment costs. Dust collectors possess an advantage with lower overall operating costs, but in this case it is necessary to adopt explosion protection measures.

Links

Used Products

Dust Collector VARIO eco >>

Capturing Devices >>

Filter Element KLR-Filter >>

Explosion Protection

Information about "Explosion Protection According to ATEX" >>

Set and Guidelines

TA-Luft: Air Pollution Control - Emission Standards >>

VDI 2262-3: Air Quality in the Workplace - Clean Air Recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>