Extraction of Graphite Dusts from Machining

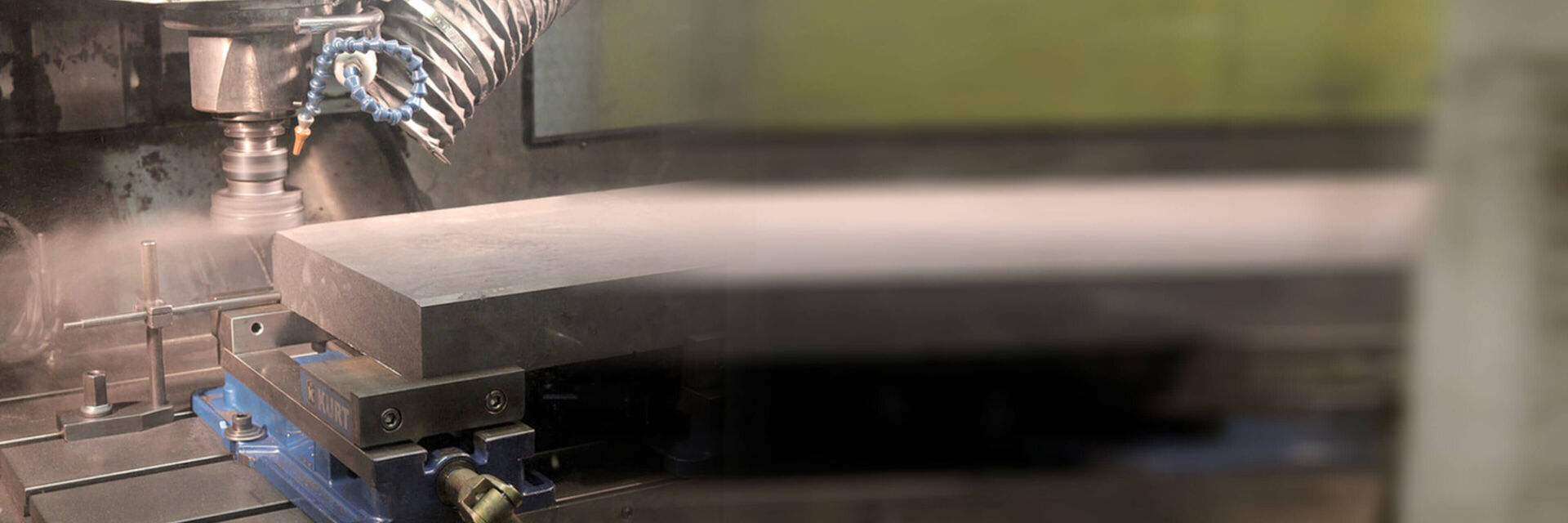

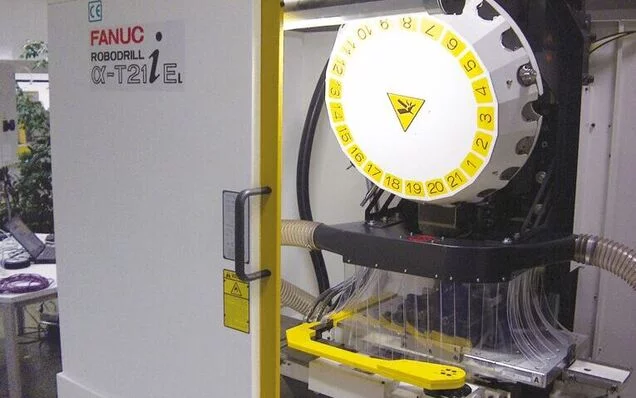

The processing of graphite materials by turning, milling, drilling or grinding during metalworking generates fine dust inside the work area. This dust can permeate machinery, the workplace, and the surrounding environment. High efficiency dust separation systems are required to prevent potential health risks and to adhere to regulatory guidelines in the management of graphite dust, as well as to increase machinery effectiveness and reliability.

Graphite Dusts are Optimally Captured and Reliably Filtered

Dust collectors of the L-CUT and VARIO series are suitable for the extraction of graphite dust from machine tools.

The capture elements are optimally adapted to the function of the machine tool and to the travel paths of the axes.

Besides an ignition source-free design, a spark pre-separator can further reduce the fire risk.

Graphite dusts are often categorized into St1 dusts (explosive dusts). In most cases, the minimum ignition energy is sufficiently high that explosion protection measures can be omitted.

Links

Used Products

Dust Collector VARIO eco >>

Dust Collector L-CUT >>

Capturing Devices >>

Set and Guidelines

TA-Luft: Air pollution control - emission standards >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>