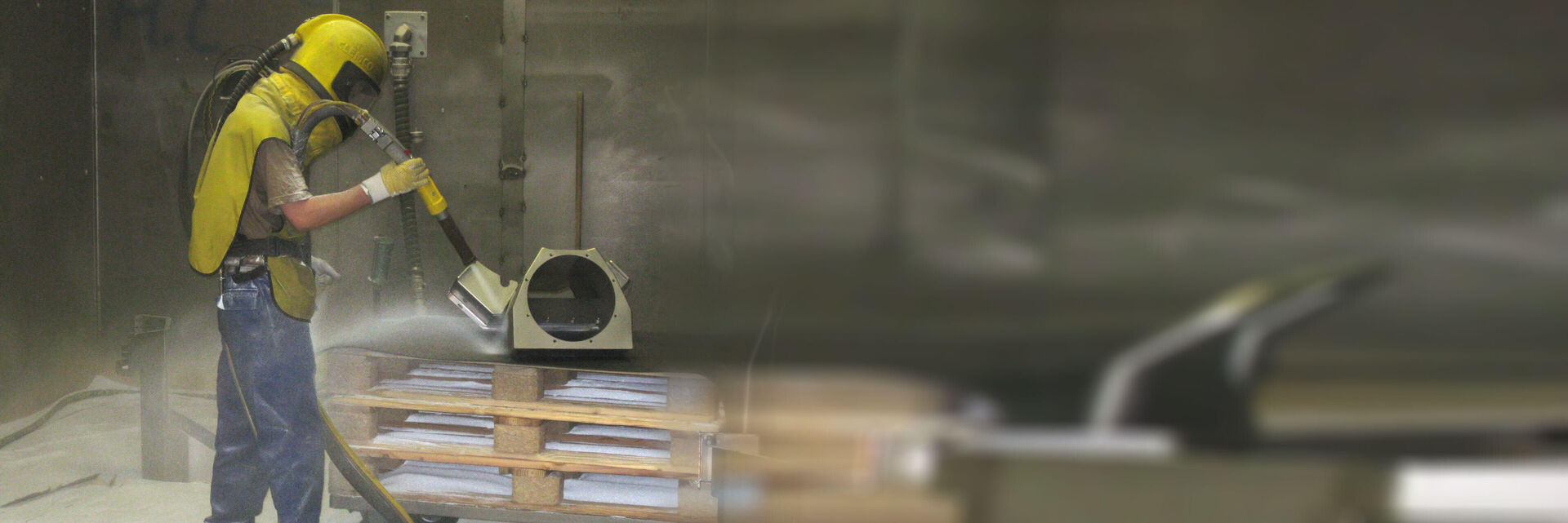

Extraction and Collection for Blasting Processes

Various blasting applications such as non-abrasive blasting, surface refinement blasting or shot peening generate a variety of dusts (e. g., metal, aluminum, magnesium, plastics, etc.) from physical abrasion. These dusts must be thoroughly extracted and collected for process-specific reasons, as well as industrial and environmental regulations.

The mingling of blasting material and blasting agents generates multiple dust combinations.

When designing an extraction system, it is necessary to take into consideration the dust characteristics, the applicable laws and regulations, as well as the customer's requirements. The increased volume of dust, the dust characteristics (e. g., combustible, explosive, harmful, organic or mineral, dry or oily) or the design of the blast machines, are all influencing factors in the design process.

In addition to the extraction process, it is also necessary to clarify whether the transport of blasting abrasives will have an additional impact.

Suitable Solutions for Every Blasting Process

Dust collectors and wet separators are both applicable for the extraction and collection of dust from blasting processes. The right choice is facilitated by the wide product range of Keller and the expertise to be able to find an optimal balance of required system technology as well as investment and operating costs.

The design of an optimal dust extraction system shall happen individually due to various factors (process, installation situation, external factors, etc.). The result are various potential solutions which might require additional pre-separators or fire and explosion protection measures.

Some of our Installed Plants

These customers rely on our extraction systems during blasting.

MTU Aero Engines, Friedrichshafen - Germany

MTU Aero Engines, Münich - Germany

Hirschvogel Automotive Group, Denklingen - Germany

Daimler AG, Mettingen - Germany

Nemak Dillingen GmbH, Dillingen - Germany

... and many more!

Links

Used Products

Dust Collector VARIO eco >>

Dust Collector PT-Filter >>

Dust Collector JET-SET >>

Single Collector TR-1 >>

Venturi Wet Separator VDN >>

Compact Wet Separator HydronPlus >>

Capturing Devices >>

Pre-Separators >>

Filter Element KLR-Filter >>

Explosion Protection

Information about "Explosion Protection According to ATEX" >>

Back Pressure Flap ProFlap >>

Flameless Pressure Relief ProVent >>

Flameless Pressure Relief ProPipePlus >>

Set and Guidelines

TA-Luft: Air Pollution Control - Emission Standards >>

42. BImSchV: Avoiding Legionella Risk in Wet Scrubbers >>

VDI 2262-3: Air Quality in the Workplace - Clean air Recirculation >>

TRGS 900: Occupational Limit Values in the Workplace >>

TRGS 560: Luftrückführung bei krebserzeugenden Stäuben >>

TRGS 561: Processing of Carcinogenic Metals >>

TRGS 528: Welding Operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, Brushing and Polishing of Aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace Ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium Processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive Environments >>

TRBS 727: Avoiding Ignition Hazards Created by Electrostatic Charges >>

VDI 2263-6: Fire and Explosion Protection for Dust Extraction Systems >>