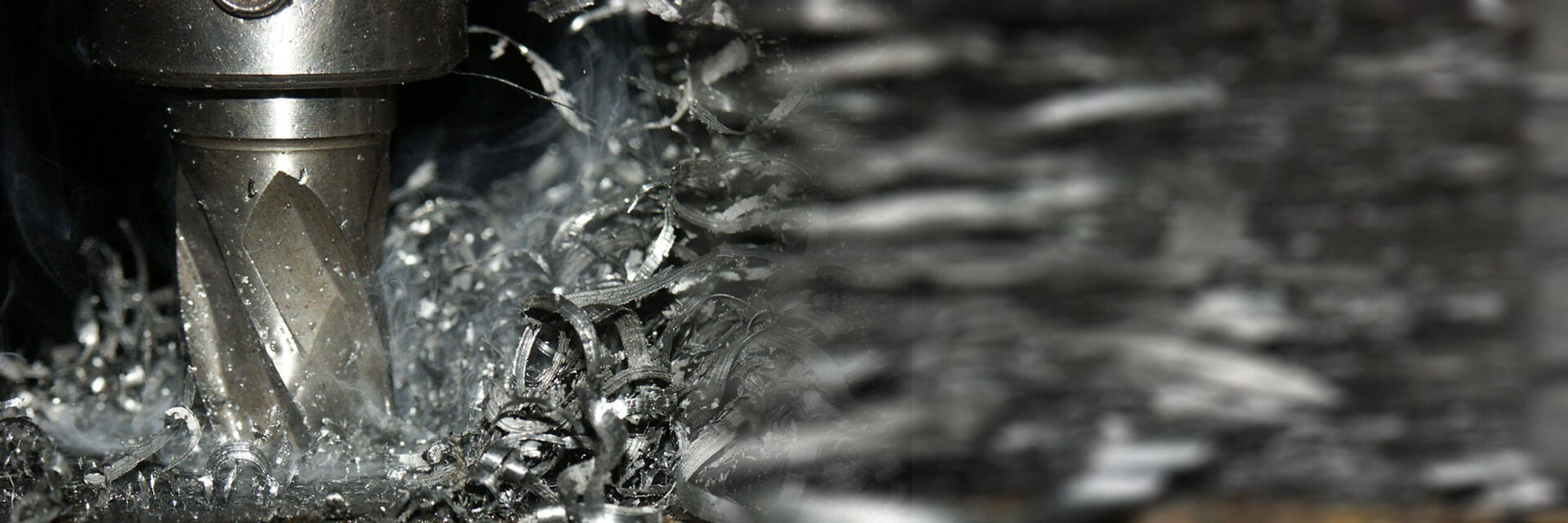

Safe and Reliable Extraction of Metallic Dusts, Coolants and Aerosols from the Machining Area

Three factors are relevant for designing suitable filtration technology in the machining of metal workpieces:

- Type of machining: turning, milling, sawing, drilling, etc.

- Application of coolants: oil, emulsion, MQL

- Materials: grey cast iron and high carbon steel, light metals, non-ferrous metals, as well as alloys

The machinery area must be kept clean, and it must be ensured that the contaminated air cannot escape.

Additional factors to be considered in the design:

- Coolant pressure

- Internal dimensions of the machine

- Size of the machine opening (for loading of workpiece, tool exchange)

- Harmful characteristics of materials to be separated

The Suitable Extraction System for Any Application.

A variety of solutions depend on the process and the coolant used:

Oil: AERO oil mist separator;

Coolant: ENA coolant mist separator;

MQL: TR-1 dust collector or VARIO with FLEXI-P;

Dust collection: VARIO dust collector or UNI-STAR

Another vital consideration is whether the extracted air can be recirculated back into the production area.

The capture elements can be designed or optimized individually based on a flow simulation to significantly improve the reliability of the entire system.

To the product page "Emulsion and Oil Mist Separator"

Coolant and oil mist separatorsLinks

Used Products

Dust Collector VARIO eco >>

Single Separator TR-1 >>

Oil Mist Separator AERO >>

Emulsion Mist Separator ENA >>

Capturing Devices >>

Filter Element KLR-Filter >>

Explosion Protection

Information About "Explosion Protection According to ATEX" >>

Back Pressure Flap ProFlap >>

Flameless Pressure Relief ProPipePlus >>

Set and Guidelines

TA-Luft: Air pollution control - emission standards >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>